You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fuel Engine (New Design by us) (1 Viewer)

- Thread starter DaveRenk

- Start date

Wes

Nitro Member

If money and develoment time were no object......

5.200" bore spacing, billet blocks, apply the most common bore/stroke combination in use today, single overhead cam design (like the Ford 427 Cammer and the modern-day 4.6L engines), two-valves per cylinder (with a strict intake valve size restriction of 2.25"), modular block design (removable inner-sleeve banks, removable pan/main rail, etc.), "spin-through" valve-to-piston orientation so if the valvetrain stops the pistons can't hit open valves, ability to remove cylinder heads without removing the intake manifold, in-deck 18 head bolt pattern, modular camshaft/rocker carriers, use current combustion chamber design, and...........could go on for days. But the internal designs would all be spec per rules limitations to keep C/R at 6:1.

Fuel system side...take a page from modern electronic engine management of diesel and now gasoline engines and use LARGE electrically controlled direct combustion chamber injectors. 8 large electromagnet nozzles that deliver the fuel at the 12 o'clock location in the chambers. Use the "common rail" design where fuel is pumped into an internal galley in each clyinder head. You'd need an electricity source to fire these big squirters...something in the 24-36 volt range. Have a common "spec" digital management processor that would control fuel and timing maps. Allow the systems to possess a certain amount of closed-loop operation to adjust for "cold" EGT readings...no more dropped cylinders. Also engineer safety functions to cut all fuel flow when crankshaft and/or camshaft accelleration slows dramatically in the event of mechnical failure...no more firebombs.

External crank-driven superchargers would need to remain in place. It's easier to mandate pulley size and teeth number than wastegate or blow-off-valve settings with turbos. Although...centrifugal blowers might be an interesting excersize.

Late night thoughts and musings.

5.200" bore spacing, billet blocks, apply the most common bore/stroke combination in use today, single overhead cam design (like the Ford 427 Cammer and the modern-day 4.6L engines), two-valves per cylinder (with a strict intake valve size restriction of 2.25"), modular block design (removable inner-sleeve banks, removable pan/main rail, etc.), "spin-through" valve-to-piston orientation so if the valvetrain stops the pistons can't hit open valves, ability to remove cylinder heads without removing the intake manifold, in-deck 18 head bolt pattern, modular camshaft/rocker carriers, use current combustion chamber design, and...........could go on for days. But the internal designs would all be spec per rules limitations to keep C/R at 6:1.

Fuel system side...take a page from modern electronic engine management of diesel and now gasoline engines and use LARGE electrically controlled direct combustion chamber injectors. 8 large electromagnet nozzles that deliver the fuel at the 12 o'clock location in the chambers. Use the "common rail" design where fuel is pumped into an internal galley in each clyinder head. You'd need an electricity source to fire these big squirters...something in the 24-36 volt range. Have a common "spec" digital management processor that would control fuel and timing maps. Allow the systems to possess a certain amount of closed-loop operation to adjust for "cold" EGT readings...no more dropped cylinders. Also engineer safety functions to cut all fuel flow when crankshaft and/or camshaft accelleration slows dramatically in the event of mechnical failure...no more firebombs.

External crank-driven superchargers would need to remain in place. It's easier to mandate pulley size and teeth number than wastegate or blow-off-valve settings with turbos. Although...centrifugal blowers might be an interesting excersize.

Late night thoughts and musings.

Wes

Nitro Member

Simplicity and 24-fewer valves to purchase per engine if the dream engine were a dual overhead cam, 4-valve design like the McGee or Shubeck Eagle (which, by the way bears an amazing resemblance to the 4.6L DOCH 32V Cobra and Mark VIII motors Ford made...12 years after they got a first-hand look at John's motor). I'd run the mags and fuel pump off the front of the cams/valve covers like they did, though.

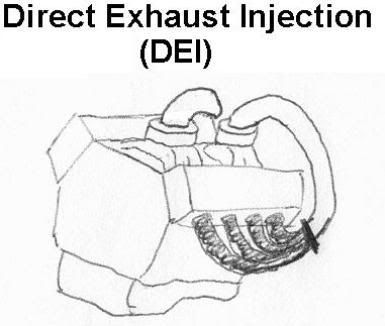

Here's my best design:

I don't think that there is enough oxygen available in the exhaust for the motor to make good HP with your design.

see below

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

joking

__

Nitro Member

I don't think that there is enough oxygen available in the exhaust for the motor to make good HP with your design.

see below

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

joking

Yeah, but it would slow the fuel classes down.

Paul

Nitro Member

Yeah, but it would slow the fuel classes down.

Hey, you could be on to something here, EGR for the nitro classes, not only slow the cars down but also help limit global warming.

I can see the NHRA getting behind this one!

Paul T.

Similar threads

- Replies

- 10

- Views

- 3K

- Replies

- 0

- Views

- 2K

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)